THE PROCESS

THE PROCESS

7 TO 12 STEPS TO DO A CAR SEAT

Founded in 1988 with 183 employees, COINDU’s core business is the production of seat covers for different OEMs. Today, COINDU has over 4.800 employees worldwide and is known amongst the major brands for the quality of its products and the flexibility of its manufacturing process. Trying to respond positively to the expectations of our customers is the cornerstone of the COINDU Group. This ambition is transmitted by our employees as well as our partners and suppliers.

STEPS TO LEATHER A CAR SEAT

WAREHOUSE

Once received, the leather hides are controlled considering several criteria, some quantitative such as thickness, and also qualitative such as patterns or visual appearance of the hide surface.

LEATHER INSPECTION

Once received, the leather hides are controlled considering several criteria:

• Quantitative: thickness and others;

• Qualitative: patterns or visual appearance of the hide surface.

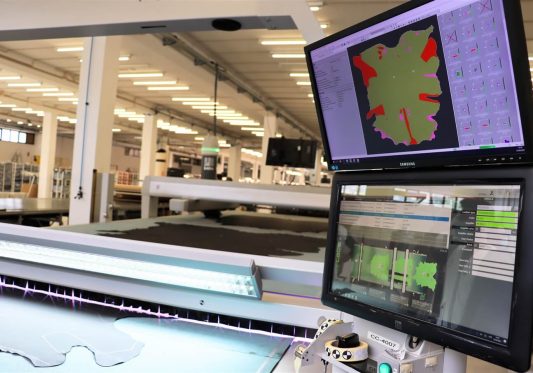

LEATHER CUTTING

The leather parts are supplied to the cutting area according to the FIFO principle. They are visually controlled once more, placed on the automatic cutting machine and scanned. The so-called automatic nesting follows and the leather parts are made into patterns, which in turn make up the final parts.

LEATHER SKIVING

Once cut, the parts need to be prepared for sewing. To ensure that the sewing complies with the standards, the edges of the parts are skived, thus ensuring minimal grain and roughness on the areas to sew.

LEATHER LAMINATION

Most customers require foam on the back of the leather parts to obtain a special fit. In the lamination process, foam and leather are thermally sealed, exiting the laminating machine as a single piece.

CUT PARTS INSPECTION

After lamination, the individual parts are subject to quality evaluation. Each part is stamped to ensure that it is 100% compliant, and to ensure its traceability.

FABRIC CUTTING

All seat covers require some type of fabric or PVC materials. These parts are cut in automatic machines with drills and blades able to process several layers of raw material at once. At the end of this process, the operators inspect the parts to ensure compliance with quality standards.

PREPARATION OF COMPONENTS

All materials required for a seat cover are transported to the sewing area, already prepared in accordance with the production order (OF). In the preparation area, the operators have all the necessary materials (synthetics and leather) needed for sewing a seat cover.

SEWING

The sewing lines are laid out according to the project and customer, and have a maximum of 14 operators. These autonomous, multi-purpose and high performance lines are called GAPs.

FINAL INSPECTION

The final inspection is included in the GAPs, where the covers are inspected and controlled. Some additional sewing operations can be performed in the inspection area.

PACKAGING

The packaging area is where all seat covers are placed in cardboard boxes, as requested by the customer. Orientation, protection and quantities are some typical requirements for each individual box. All parts are label controlled, thus giving COINDU total control over the traceability process.

EXPEDITION

In the expedition area, the labels are printed for each pallet and the necessary documentation is prepared for the delivery of the finished covers to the customer. Depending on the final customer, special documents such as pick lists, dispatch notes or custom bills are issued.

STEPS TO A VINYL / TEXTILE CAR SEAT

WAREHOUSE

Once received, rolls are controlled considering several criteria, some quantitative such as width and length, qualitatively mainly the appearance and color.

FABRIC CUTTING

Seat covers made of fabric or PVC materials, are cut in automatic machines with drills and blades able to process several layers of raw material at once. At the end of this process, the operators inspect the parts to ensure compliance with quality standards.

PREPARATION OF COMPONENTS

All materials required for a seat cover are transported to the sewing area, already prepared in accordance with the production order (OF). In the preparation area, the operators have all the necessary materials (synthetics and leather) needed for sewing a seat cover.

SEWING

The sewing lines are laid out according to the project and customer, and have a maximum of 14 operators. These autonomous, multi-purpose and high performance lines are called GAPs.

FINAL INSPECTION

The final inspection is included in the GAPs, where the covers are inspected and controlled. Some additional sewing operations can be performed in the inspection area.

PACKAGING

The packaging area is where all seat covers are placed in cardboard boxes, as requested by the customer. Orientation, protection and quantities are some typical requirements for each individual box. All parts are label controlled, thus giving COINDU total control over the traceability process.

EXPEDITION

In the expedition area, the labels are printed for each pallet and the necessary documentation is prepared for the delivery of the finished covers to the customer. Depending on the final customer, special documents such as pick lists, dispatch notes or custom bills are issued.